January 21, 2021

DPM-EduSeries Post 5: Friction Welding

For our latest post in our DPM-EduSeries, we will be looking at Friction Welding!

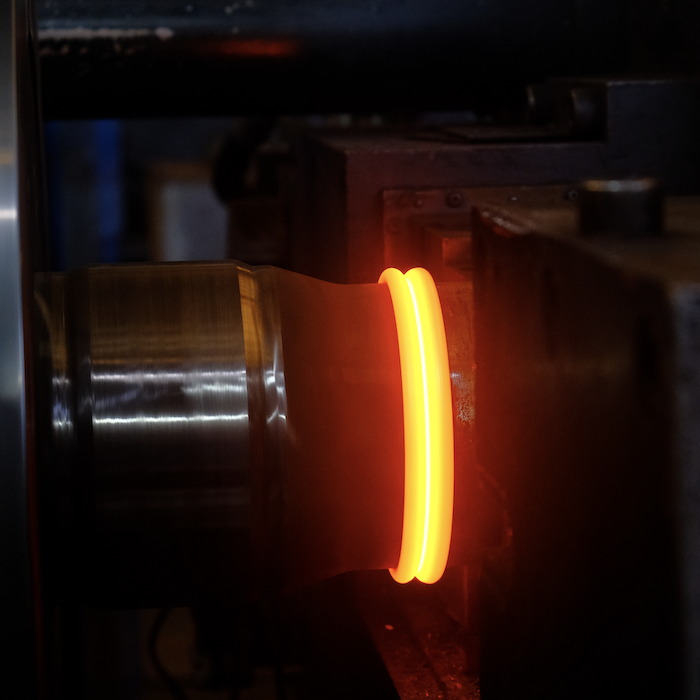

Rotary Friction welding is a solid-state welding process that generates heat through mechanical friction between two workpieces whereby one is spinning and one is stationary. When the spinning piece is up to speed, a lateral force is applied to the two workpieces. This friction and thus heat generated combined with the pressure from the lateral force plastically displaces and fuses the material. DP-Master has two sets of Rotary Friction Welders from Manufacturing Technology, Inc. (MTI). The tool joints are inserted into the rotating chuck and the tube on the nonrotational chuck. After friction welding, the pipe moves to the post-weld heat treatment area.

Stay tuned to our next post in our DPM-EduSeries as we explain more about Post-Weld Heat Treatment!

#DPMaster #DrillPipe #DrillString #DPMEduSeries #Manufacturing #DPM#FrictionWelding