OVERVIEW

The DPM-MT® connection was developed based on a Fit for Purpose principle to provide users with a connection that has a substantial increase in torsional strength compared to API or 1st Generation Double Shoulder connections with the ability to run quickly and efficiently in very severe drilling operations.

A well engineered design which evolved from the original DPM-DS connection enhanced the mechanical capabilities while still retaining the principle of cost efficiencies in the DPM-MT® connection.

Thanks to the increased torsional strength, the DPM-MT® connection delivers superior performance in Extended Reach Drilling (ERD), High Pressure High Temperature (HPHT) and Ultra Deep Drilling while maintaining similar running speeds as API connections.

The DPM-MT® connection is designed for the most challenging drilling operation while maintaining the ease of use and repair economics.

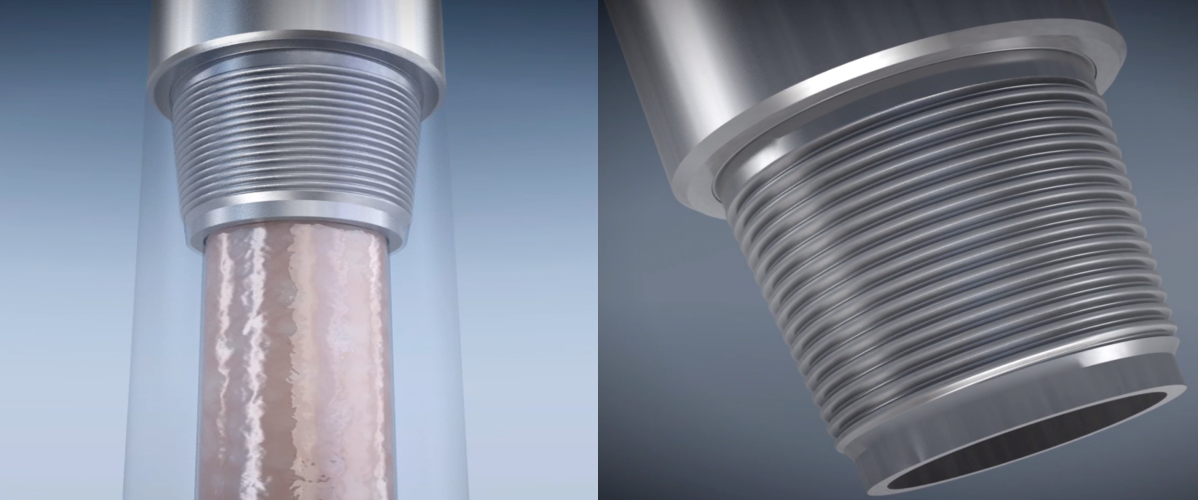

Streamlined Profile

DPM-MT® connection provides geometric flexibility which improves hydraulic performance with a larger ID or fishing ability without compromising torsional capacity with a reduced OD when compared with API connections.

The smooth internal bore across the secondary make-up shoulder allows smoother fluid flows with minimised turbulence and energy loss inside the connection.

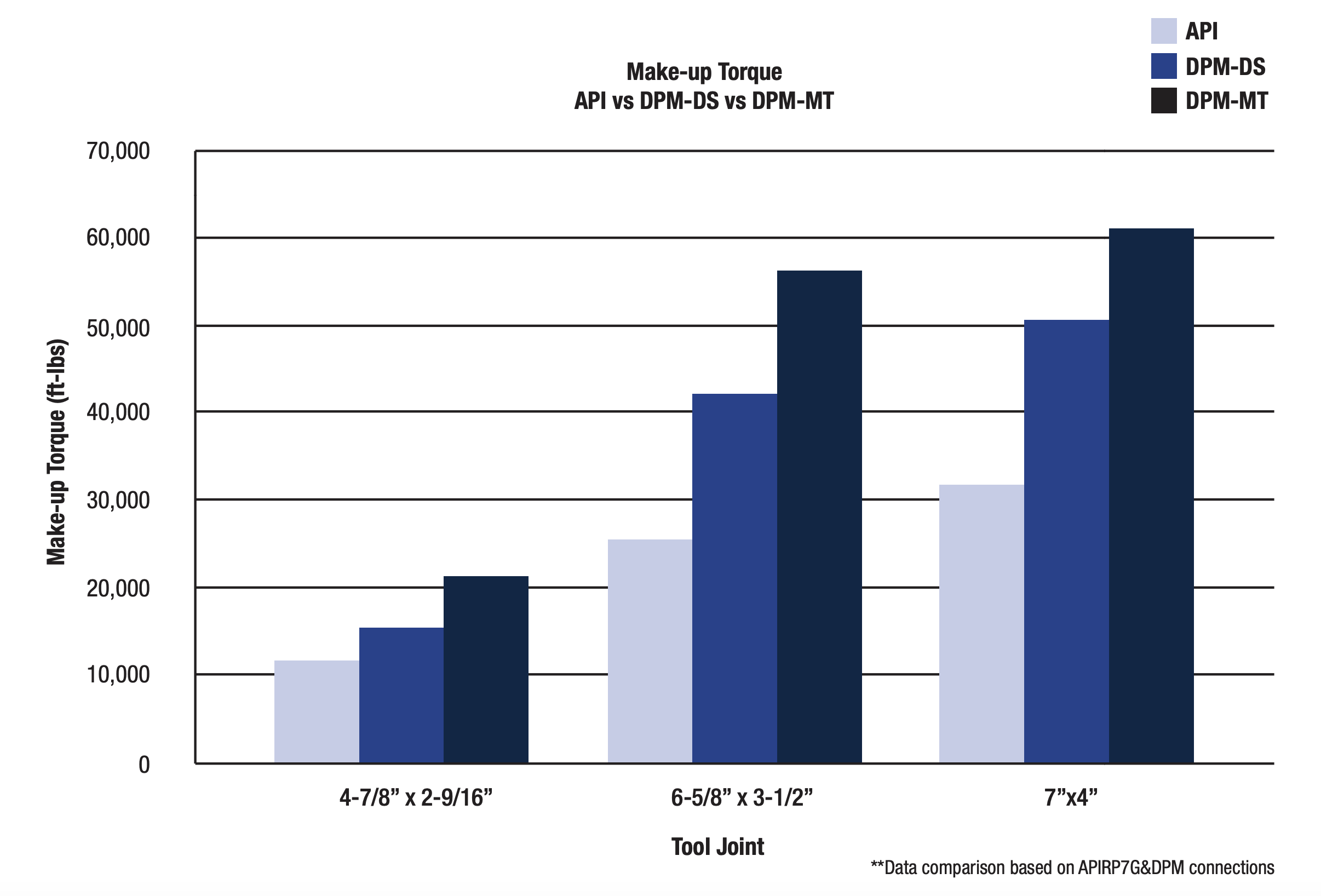

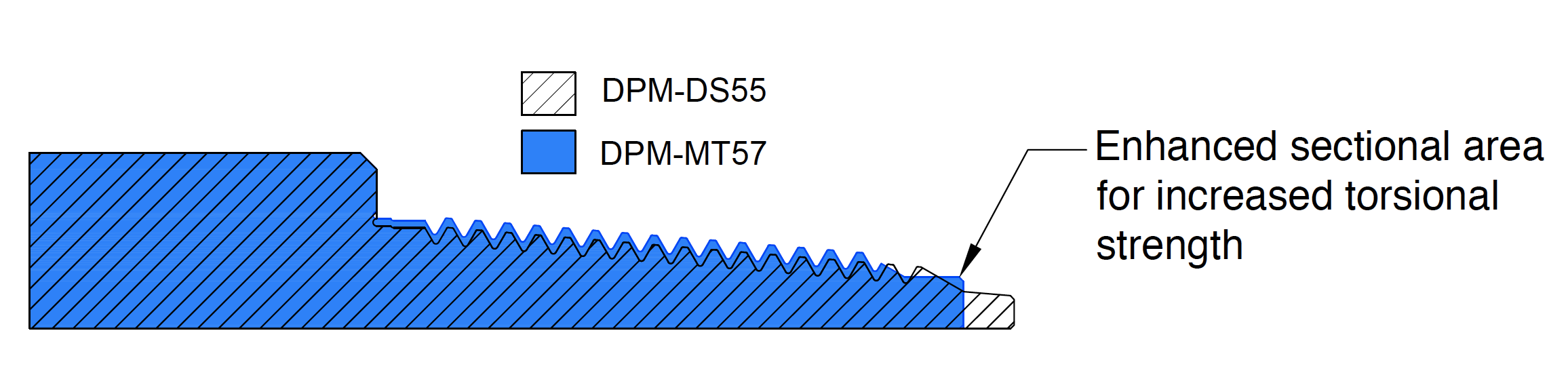

Increased Torsional Strength

Double shoulder design provides additional torsional strength to sustain higher make-up torques. The higher frictional make-up load is absorbed by the secondary make-up shoulder. Added steel at critical areas further increases the torsional strength of the connection.

Efficiency

The DPM-MT® connection features an API taper and thread form which allows deeper stabbing and more stability during make-up. It takes an average of 5 revolutions from stab-in to full make-up thereby, making the connection operator friendly. Stabbing guides are not required to be used. The DPM-MT® connection is designed to be robust yet simple to use.

Savings

With the API taper, there is minimum tool joint recut loss. In addition, readily available API cutting inserts can be used therefore minimising maintenance costs and shorter turnaround time. Being able to stab deeper, there is less stabbing damage. Overall, the DPM-MT® connection is extremely cost effective over entire life cycle.

3rd Party Testing

With the API taper, there is minimum tool joint recut loss. In addition, readily available API cutting inserts can be used therefore minimising maintenance costs and shorter turnaround time. Being able to stab deeper, there is less stabbing damage. Overall, the DPM-MT® connection is extremely cost effective over entire life cycle.

Positive Feedback and Experience

- Over 15,000 joints sold and used

- Proven product by various operators including Statoil for over 5 years

- Successful application in the North Sea, Australia, South East Asia including difficult extended reach wells over 8,000m

Sizes and Grades

- Full range of sizes for all drill pipe from 2-3/8” to 6-5/8” OD

- Wide range of steel grades including sour service and high strength

DPM-MT® Mechanical Characteristics